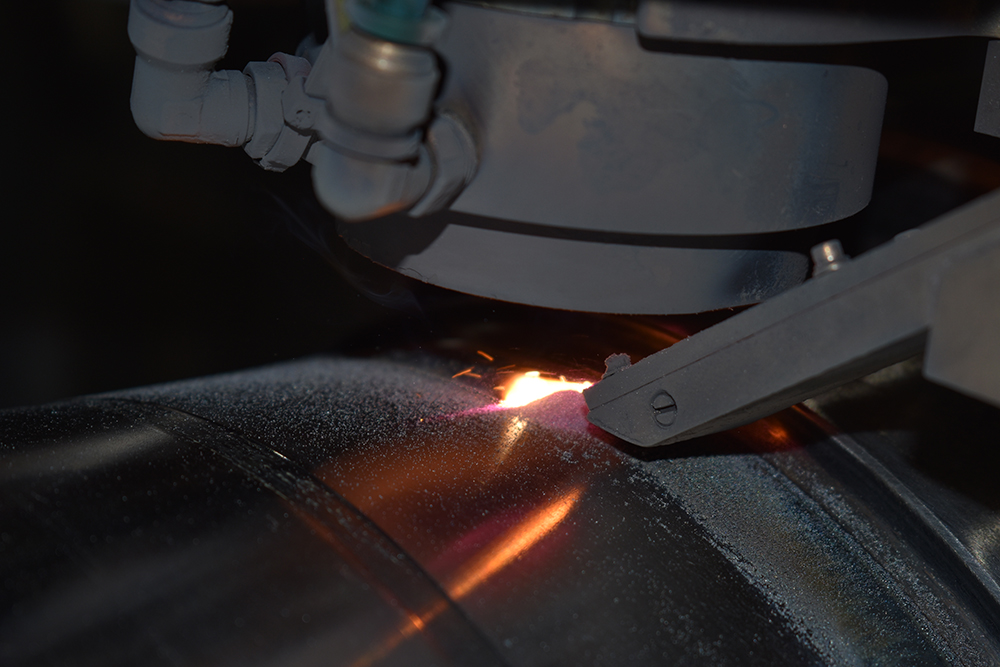

Laser Clad Welding and Other Welding Services

When it comes to the equipment you need to get your work done, we know that precision can make the difference between success and failure. At CB HYMAC, we offer laser clad welding held up to cutting-edge standards so that we can meet every requirement you bring to us. Your work can only be as accurate as your machinery allows, and we’re here to raise that standard.

CB HYMAC is a division of Cleveland Brothers, the Cat® dealership in your local area. We take quality seriously and only offer repairs and rebuilds that are certified to Cat manufacture standards. We know that money saved means better business for you, so we offer laser clad welding. Instead of purchasing brand new equipment or components, you can request our laser cladding services and bring your old machinery back to full functionality. We use high-quality laser cladding to reduce wear and corrosion on your components, ultimately extending their life and work capacity.

Our laser clad welding capabilities make many options available, including component salvaging to save you money. As a certified Cat Component Rebuild Center (CRC), it’s important to us that we stay up-to-date in our industry. To do so, we take regular advantage of our exclusive access to service bulletins and technical support from Caterpillar®.

The Details of Our Welding Services and Equipment

Our in-house engineers will accurately design and process materials that perfectly match your specifications. With our laser clad welding, we use complete laser and robotic integration as well as dual Computer Numerical Controlled (CNC) programmability for that type of control. Our 11-axis robotic system and twin rotary positioning stations mean we can weld to extreme detail for the precise requirements of your unique machinery.

Our goal is to bring your components back to exact tolerances and specifications using our precision welding and machining. Depending on your requirements and the condition of your equipment, your request might require different types of welding. With CB HYMAC, you’ll have many options available to you. The welding processes we perform are:

Our goal is to bring your components back to exact tolerances and specifications using our precision welding and machining. Depending on your requirements and the condition of your equipment, your request might require different types of welding. With CB HYMAC, you’ll have many options available to you. The welding processes we perform are:

- Stick welding

- Tungsten inert gas welding

- Metal inert gas welding

- Submerged arc welding

- Thermal spray welding (hot and cold flame spray)

The Laser Cladding Process — How Other Welding Processes Work

Laser cladding involves the processing technique of bonding one material’s surface to another in a controlled and precise manner. With laser cladding services, you experience the following advantages:

- Accurate material placement for improved performance.

- A wide variety of bonding material options to be utilized and deposited onto with little or no porosity.

- Minimal heat input for few heat affected zones, limited distortion and reduced corrective procedures.

- Easy automation and integration into CAD/CAM production work sites.

At CB HYMAC, we offer a wide range of different laser cladding techniques to accommodate your specific project needs and requirements. Each requires a specialized approach and a team of skilled, detailed experts to execute precise results — our team can work with you to determine which type of laser cladding solution works best for you.

Stick Welding

Also referred to as shielded metal arc welding, stick welding is a manual process that involves using an electric current to form an arc between the stick and the metals being joined together. Due to its simple technique and easy operation, stick welding is one of the most popular laser clad welding processes. Stick welding is primarily used for welding iron and steel materials as well as nickel and copper alloys.

Tungsten Inert Gas Welding

When you need a precise repair for thin or fine gauges of metal, tungsten inert gas welding is the best solution. This process uses an electric arc process to strike the metal surface and a tungsten electrode. Using a flow of inert gas, tungsten inert gas welding produces a better weld result, protected from impurities and oxidization. Tungsten inert gas welding uses a foot control operations for easy, fast heat adjustment and greater command.

Utilizing tungsten inert gas welding laser cladding techniques requires exceptional skill and patience. Due to its small scale weld pool, this method is best used for minor repairs and patches, particularly in instances where the laser cladding could quickly burn through the materials.

Metal Inert Gas Welding

Metal inert gas welding is the most common industrial welding process because it is faster and more versatile than alternative laser clad welding solutions. This process uses a shielding gas like carbon dioxide fed through a welding gun along with an electric arc attached to a spool of wire to melt the two metals and join them together. Metal inert gas welding eliminates the need to constantly stop and replace electrodes as long as there is wire wound around the spool. By using a constant flow of gas around the weld versus molten slag, there’s a cleaner and better weld result.Sched

This laser welding technique can be completed using semi-automatic or automatic techniques — although a constant voltage and direct current power sources are most commonly used with metal inert gas welding. When utilizing metal inert gas welding, there are four common methods of transfer including globular, short-circuiting, spray and pulsed spray.

Metal inert gas welding is often used for high volume screw and rotor applications or buildups and repair.

Submerged Arc Welding

Submerged arc welding involves forming an arc between a continuously fed electrode and the joined metal pieces. A powdered flux is used to create a protective gas shield and slag for the weld zone. This method is very versatile but is ideally utilized in butt welds for manufacturing line pipe and pressurized vessels.

Why Choose CB HYMAC for Your Laser Clad Welding?

When you pair with CB HYMAC for your laser cladding services or other machine shop needs, you’ll enjoy:

When you pair with CB HYMAC for your laser cladding services or other machine shop needs, you’ll enjoy:

- Electronically archived service records to eradicate potential future breakdowns

- Experienced engineers and machinist ready to handle equipment diagnostics and repairs

- Hydraulic hose repairs completed in a half hour or less

- Authentic Cat parts used whenever possible

- Quickly-sourced replacement parts even when hard-to-find

Contact Us Today About Our Laser Cladding Services

Our top-of-the-line laser cladding services can help your equipment meet required specifications, increasing your overall productivity and profitability. Our experienced representatives will be happy to lend support and answer questions when you get in touch. Contact us now to learn more or schedule your laser clad welding.